Rock Anchoring

Deals with the design and construction of temporary and permanent pre-stressed Structures Rock Anchors are post tensioned tendons that are secured in underlying rock or other suitable surfaces. They are durable and very cost effective. We install rock anchors for :

- Slope Stabilization

- Countering uplift pressure for Foundation Raft

- Pile load tests

Geotechnical Investigation

Geotechnical Investigation is a field of Civil Engineering that deals with the technical behavior of earth related materials. A routine Geotechnical project ideally begins with a survey of underlying materials and their physical, mechanical and chemical properties. Drilltech steps in where required for on site investigation and services on projects pertaining to :

- Residential, Commercial, Industrial Buildings

- Tunnels for Railways, Highways, Sewerage projects.

- Cement, Thermal Power, Oil Refinery, Highways and other major project.

- Hydro-electric, Pumped Storage, Pipeline, Irrigation Projects.

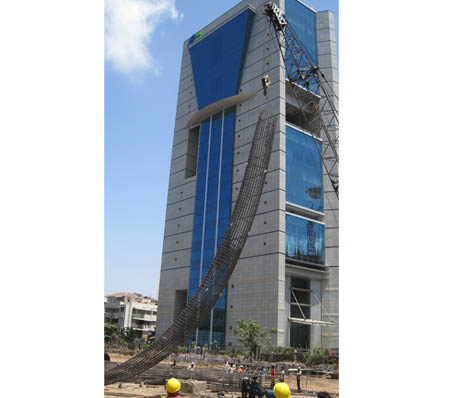

Cage Making (1200 mm - 1500 mm dia)

Piling Services

We specialize in offering end to end solutions in piling. We are often acknowledged for offering best solutions within least possible time. With the help of hydraulic rotary pile, normal rotary pile and rotary pile by HR 130 & HR 180, we redefine piling services with effectiveness. With innovative techniques and unmatched expertise, we exceed the quality standards of the industry. Our services have gained wide appreciation for timely execution and cost effectiveness.

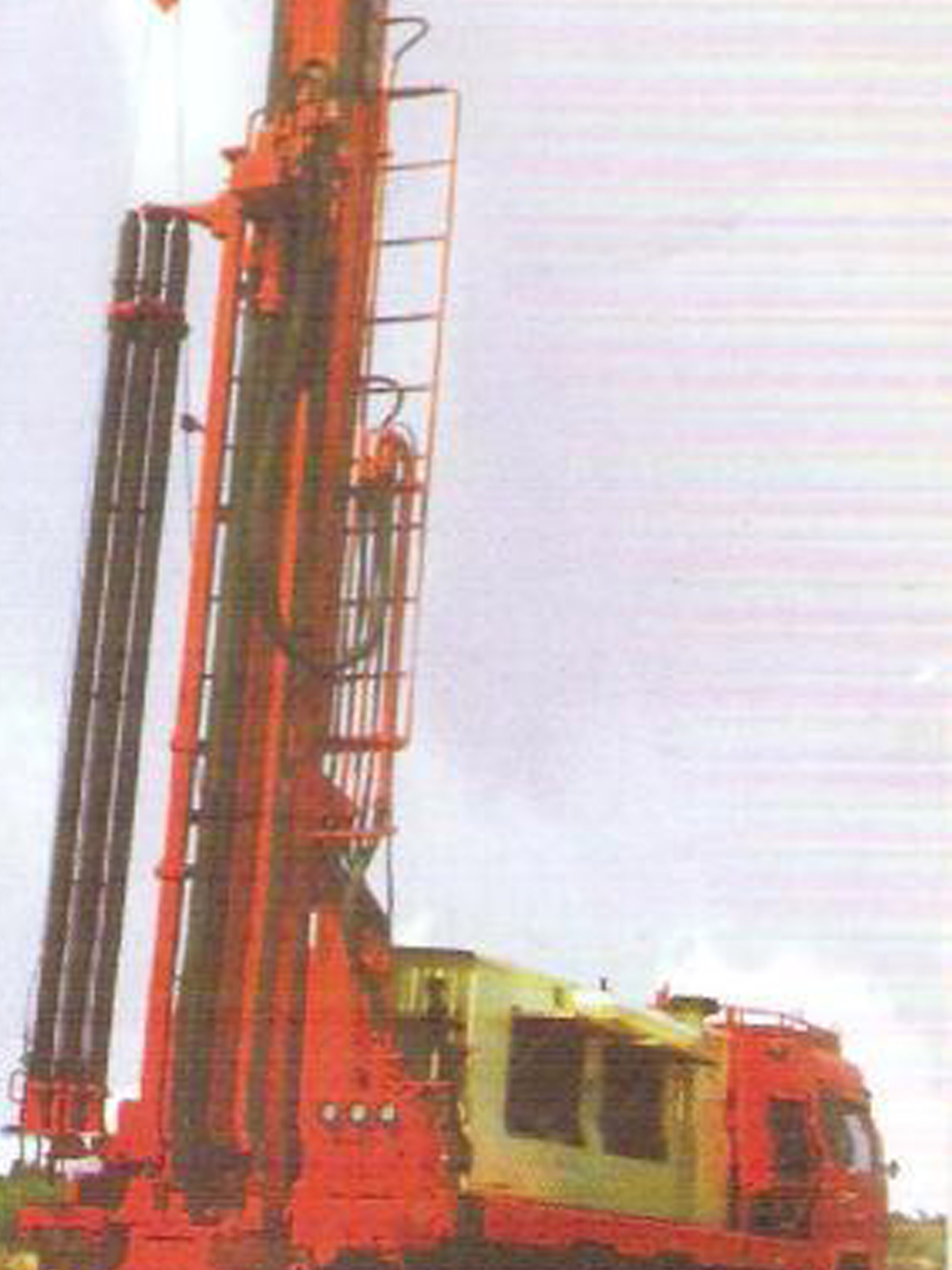

Micropiles

Micropiles are load bearing piles used to strenghten foundations or to retain walls. The advantage of the equipment lies in its installation which is relatively easy. It executes micropile projects using piles ranging from 150 mm to 300 mm in diameter. Micropiles could be done with the following Rig & Method.

These rings are only used when there is a space constraint near the existing foundation of structures & to avoid noise pollution. These ring are often used basically for Basalt or Breccia where the required quality of rock is very high By Hydraulic Rig(DTH Method): in this process the pile is directly drilled throughout to the designed depth.

Methodology of Piling

- Survey the area & mark the pile points.

- Bring the rig near pile point, Align tip of Auger with Pile Point using articulation & adjust vertically.

- Pre-bore @ 1m depth, place guide casing keeping pile point at centre & press by rotary. In case of longer casing it is placed in a similar way.

- Start Boring. Depending upon the material being bored, Drill & take out musk. After boring to the desired depth, clean the bore by using bucket.

- After the boring is finished, lower the cage in the bore using a crane or auxiliary winch of the rig. Pour the concrete using tremie pipe up to the top of the bore.

- Remove the temporary casing by crane/2nd winch.

Basalt Rock

Cutting down the hard rock encounters during the Drilling process for the pile, using corebarrel

DMC

Methodology for CAST in SITU BORED PILES (ROTARY METHOD)- Shifting of the hydraulic auger to the required pile and centre to be done accurately with the help of plumb bob.

- Auger to start the boring and the bottom casing to follow next

- The centre and the alignment of the bottom casing to be scrutinized accordingly with reference points marked at a right angle.

- The bore to be drilled and developed by the auger

- Bentonite slurry to be used if required in case of retaining walls of the bore.

- The indigenously designed auger that performs on any surface including rock to be used in developing the bore.

- Hard surfaced conical teeth made of tungsten carbide are present in the auger. Such a mechanism can develop the bore in rock also.

- The bucket shall be withdrawn from the hole and on opening bottom of hinge, the admitted muck will be discharged on ground.

- On achieving the desire strata, a series of events to follow, viz. the steel cage to be lowered followed by lowering of Tremie.

- The concreting operation to be carried out as outlined in IS 2911 sec.

Geotechnical (Soil Investigation)

GEOTECHNICAL WORKWe propose to carry out the above work, using our standard 100mm diameter Shell / bailer equipments to refusal depth, refusal being indicated as and when the standard penetration test value equals 50 for 7.5 cm standard penetration test will be conducted using an automotive drop hammer. Undisturbed soil sample will be collected in 100 mm diameter steel tube of 45 cm in length which properly wax & mark indication of depth etc on it.

Further drilling in all type of rock by calyx / Hydraulic feed- rotary method, will be carried out using ‘NX’ size diamond bits with single or double tube core barrel as & where required for higher core recovery Drilling through rock will be carried out up to 5 meter in hard rock or as advised. These rock cores will be placed in wooden core boxes. Core box clearly marked with site name, client name, Final depth & bore hole no.

On completion of the site, soil water and rock samples obtained from the boreholes will be handed over to you for safe keeping with detailed soil investigation field report. Later all field report with Bore log & laboratory report with Geologist report will be given to you after 8 days of sample send in laboratory test.

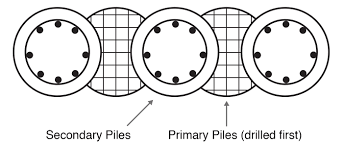

Secant Pile

Primary piles will first be installed alternately, these piles will be of un-reinforced concrete of M15 mix with a minimum slump of 175mm. These piles do not have to be installed to the same length as the secondary or intermediate or reinforced piles which follow. Secondary piles will then be installed between the primary piles, 24 hours after the construction of primary piles. Pile overlap will be 0.5% of pile length or 75mm or 12% of pile diameter, whichever is more. Thus by the 2nd criteria, pile centre to centre spacing will be D-75mm. The secondary piles will be reinforced piles of M25 concrete strength with a minimum slump 150mm. These piles will be installed with rotary hydraulic piling rigs, equipped with a heavy coring pipe whose cutting edge toothed and enables to cut into the concrete of initial primary piles.

Tremie Concrete